TANGALIYA WEAVING OR DAANA WEAVING

Tangaliya weaving, also known as Daana weaving is practiced in Surendranagar district of Gujarat. Mainly practiced by the Dangasia community, this form of weaving requires high skill level and an eye for accuracy.

Tiny dots of extra weft are twisted around a number of warp threads, giving an effect of bead embroidery to the fabric. This intricate process of twisting extra weft while weaving creates beautiful geometrical patterns and forms. The essence of Tangaliya weaving is the compositions created by colourful dots, which is simultaneously created on both the sides of the fabric.

History of Tangaliya Weaving Or Daana Weaving

This indigenous craft has deep rooted origin and history of about 700 years embedded in the Saurashtra region of Gujarat. Legend says that a young boy from the Bhadwad (shepherd) community fell in love with a girl from weaver community and married her.

This displeased his family; as a result the boy and his bride were not welcomed by the family. So he settled down with the weavers’ community and continued herding sheep.

He learnt weaving from his in-laws and started using wool from the sheep he herds. Thus the art of Tangaliya weaving came into being.

Another version of the story says that the boy had a hard time earning bread and butter after he was disowned by his family. His parents were saddened seeing this and offered a proposal to him.

They provided sheep wool and grains to him and in return he weaved shawls and other garments for the shepherd community. He took shawl weaving to another level by introducing thread beads thus developing Daana weaving.

Tangaliya is practicedin26 villages out of which we visited three villages: Vastadi and Dedadrain Wadhwan taluka and Derwada in Lakhtar taluka. Traditional Tagaliya weaving is practiced only in Derwada village. In other villages the craft has been contemporised according to market needs.

Producer Community

History

Tangaliya weaving and Dangasia community originated simultaneously. According to one of the weaver, it was originated by a young boy from Bhadwad community who was shunned by his family for marrying a girl from the Wankar community (weaver community).

The couple made their living by weaving shawls using the wool provided by the Bhadwads. In this way a new community, the Dangasiya community, came into being which connected the Bhadwadsand the Wankarsin a self-sustaining way.

The word Dangasia has been derived from the word Dang, which means a stick in the vernacular language, signifying the stick used by shepherds to herd their sheep.

Occupation

The Dangasias shared a symbiotic relation with the Bhadwads, where the latter provided wool and the former wove garments for them. A barter system existed between the two where overheads were paid by the Bhadwads in the form of grains or anything else required by the Dangasiyas. The range of garments included Tangaliya, Galmehndi, Dhablo, Dhunsu and Charmalia.

The women of the household assisted the master weaver in supporting tasks like wool cleaning, yarn preparation, yarn dyeing, bobbin preparation and warping.

With the emerging trends and the introduction of less expensive, printed textiles in the market, the Bhadwads lost interest in hand woven textiles, as a result the Dangasias lost their only source of income.

In the present time many traditional weavers and their descendants are sustaining themselves by working as laborers in factories or on farms. A few have migrated to cities looking for better opportunities.

Religion and beliefs

The Dangasias follow Hinduism and believe in a number of Gods and Goddesses depending on the region and the tradition they follow. They are devout believers in Chamunda Devi, a form of the goddess Parvati. On the eighth day of Navratri, in October, they gather to worship this goddess.

Dangasias also worship Shiva, Shakti, Ganesha and Krishnaalong with goddesses Pitthad mata, Machu mata, Kalka mata. They are the followers of Jodhalpir who is said to have lived 750 years back. His shrine is situated near Bawla in Gujarat and is regularly visited by the Dangasias all over Gujarat.

They celebrate all major Hindu festivals like Holi, Diwali, Uttarayan and Janmashtami besides actively participating in other local festivals and fairs.

Raw Materials

The Dangasias have experimented with many different types of yarn over the years, ranging from wool to cotton to acrylic. Cotton, silk and acrylic yarn is the most important raw materials used to make contemporary Daana weaving garments. Depending upon the orders and market requirements, combinations of these yarns are used.

Wool

Traditionally, Tangaliya weaving was done majorly in wool. It was hand spun in situ hence readily available. Due to the availability of ready-made yarns of a variety of fibres, hand spun wool is not used anymore.

Cotton

Due to the change in market conditions in the last ten years, the

Dangasias have started using cotton to produce a diverse product range. Cotton is bought from Ahmedabad and Surendranagar.

Acrylic

Now-a-days the Dangasias prefer acrylic yarn over wool since it is less expensive, easily available and comes in a variety of colours. Most consumers do not mind the change in texture. This yarn is mainly used for making the thread beads or dots in the Tangaliya weaving.It is also purchased from Ahmedabad.

Silk

Silk yarn is used only for making products for high-end market. Eri and mulberry silks are the most predominantly used yarns. It is mainly purchased from Surendranagar.

Tools

Warping frame and bobbins

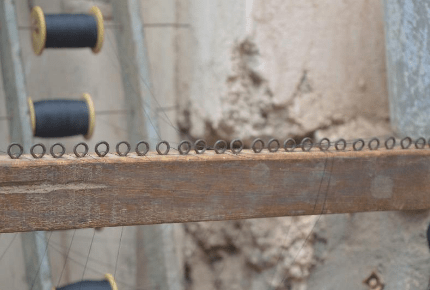

Warping frame is a wooden frame with four columns. Metal rods are inserted through columns which hold the bobbins. A wooden beam, with metal rings attached, is used along with this frame to segregate each warp thread.

Warping frame

Pit loom

It is a flying shuttle counter balanced pit loom with two shafts and two paddles. The reed is held by the sley which is suspended from an overhead horizontal beam by ropes.

The woven cloth is rolled on the cloth beam, which lies in front of the sley facing the weaver. The width of the loom is about 30 inch and a maximum of about 15 inch cloth can be woven on it.

Panas

it is made of bamboo. It has two longitudinal sections which are ¾ inch in width and are held together by string where the tow ends overlap. The two opposite ends have sharp pins attached through which it is attached to the cloth. It helps in maintain the width of the cloth and prevents from shrinking.

Other tools (Heddle hook, Shuttle, Scissors, Cleaning brush, Blade)

Heddle hook is a hooked implement used to thread a strand of the warp through the eye of the heddle.

Shuttle or khanthalo is a boat shaped tool, made from Shisham, which holds the weft reel in the scooped out area. Scissors and blades are used to cut threads when required. Cleaning brush or Jhaadu is used to clean the loom.

Process

The process of tangaliya weaving is needs accuracy and high skill level. The whole process can be divided into two stages:

Warping

For warping, first the yarn bundle is converted into small rolls called bobbins through the process of reeling, which is done on the charkha (spinning wheel). One person is required to do this task. It is generally done by the weaver’s wife. It takes five to ten minutes to reel one bobbin.

The reeled bobbins are installed in the warping frame shown in photograph five. In one frame forty bobbins can be installed. In front of this frame a wooden beam is kept. This beam has small metal rings attached on the upper edge. On the adjacent wall, nails are fixed on which warp thread is wrapped.

Segregating threads and making warp

One strand from each bobbin is threaded from the metal ring. Forty individual threads are reeled or gathered on a wappon or wooden pegs. The threads are then guided through two adjacent columns of nails alternately. The distance between the columns is approximately five meters. There are 3200-4000 warp threads in a saree, 1800-2000 warp threads in a dress material and 1200 warp threads in a stole. It takes an entire day to complete warping.

Once the warp is ready it is knotted to the remaining ends of the previous warp on the loom. This method eliminates the elaborate process of denting and drafting. Usually, each thread is put through the healed eye alternately. Denting is done with two ends in each dent of the reed.

Weaving

The fabric is constructed in plain weave. An extra weft technique is used for creating the pattern through tiny dots. Individual dots are created by tightly twisting and wrapping coloured acrylic yarn onto pre-decided number of warp threads according to the motif. For making the dots, the weaver opens the twists of coloured acrylic yarn and separates the fibres. He then lifts two warp threads at a time and by using his thumb and forefinger, twists the acrylic fibre around the lifted thread and then levels it with the woven area. After having completed the required dots across the warp width, the ground weft is inserted, the shed is changed and the pick is beaten in.

Plain weave

Motifs

The motif vocabulary of Daana weaving mainly constitutes of the elements present in the community’s environment. Some examples are peacock (mor), plant (jhaad), Naughara, and many more. Some examples of the common motifs are given below:

Peacock

Products

Acrylic Shawl

Cotton dress material

Other Products:

•File covers

•Pillow covers

•Table runners

•Tie

•Handbags

Market of Tangaliya Weaving Or Daana Weaving

Traditionally, Daana weaving was used only to weave garments like Tangalia, Galmehndi, Dhablo, Dhunsu and Charmalia for the Bhadwad community.

It did not have any commercial market in the urban sector about a decade ago. In 2007-2008 National Institute of Fashion Design (NIFT), Gandhinagar initiated a project for the protection and revival of Tangaliya weaving.

They conducted several workshops on design application and created a range of products in different types of yarns to suite the contemporary market requirements. This opened a new door, full of opportunities, for the weavers. Their confidence was boosted which helped them to increase their clientele.

The weavers get connected to the market either through wholesale buyers or by running their private workshops. Wholesale buyers provide the weavers with looms and raw materials and the weavers work as laborers for them, earning 150-200 rupees per day.

In this case the weavers are indirectly linked to the market. Some master craftsmen, who manage their own workshops, have 6-7weavers working under them. Through exhibitions, the master craftsman becomes aware of market’s demands and increases his clientele. The final consumer can now directly approach the weaver to get customized products. Since the number of people involved in this system is reduced, the weaver gets a fair price for his work.

One of the challenges that the weavers face in marketing their products is the high price. In market, the cloth made on a power loom costs approximately thirty rupees per meter. Customers who are aware of this fact, tend to compare the price of hand woven tangaliya cloth with the one made on a power loom.

So, weavers have a hard time in explaining them about the technique and that each cloth is unique in its own way. Customers who are aware of traditional crafts and can appreciate their design aesthetics, purchase tangaliya products without any bargain.

Changes and Challenges

Major changes and challenges that the craft is facing can be summarized under two categories-Production and Social Importance.

Production

The craft has gone through major changes in terms of raw material, design application and product range.

Raw material

traditionally, only hand spun sheep wool was used for weaving Tangaliya. The process of yarn preparation was quite elaborate. During the revitalization project started by NIFT, the weavers were introduced with readily available, machine made yarns like cotton, acrylic and silk. The usage of machine made yarn fastened the production and lowered the cost of final product. One of the challenges that the weavers face in procuring raw material is the unavailability of certain coloured yarn in small amounts. The coloured yarn is majorly used for making dots or thread beads and the amount used in one product is far less than the minimum amount of yarn that they have to get dyed i.e. 100 kg approximately. So if they have to use a coloured yarn which is unavailable, they have to get the yarn dyed, which increases the final cost of the product.

Design application:

Traditional Tangaliya follow a certain colour palette that is black base with white dots and red borders. Later in 2007-2008 with the application of different kinds of yarn, which provided a huge colour palette, weavers and clients got an opportunity to play with a variety of compositions.

They started using their motifs and composed them in different layouts according to the product requirement. For example in a dress material, they arranged peacock motifs in different ways to emphasize the neck and repeated small motifs, like button, to make the entire body.

the main challenge in design application lies in understanding and coming up with new compositions without losing the character of a dot. For example, shown in the picture is the so called contemporary motif tried by some design students.

Somehow the dots have lost their essence and instead of being an abstract idea it has become a mere representation of an image of a flower.

Product range

Traditionally, Daana weaving was used only to weave garments like Tangalia, Galmehndi, Dhablo, Dhunsu and Charmalia for the Bhadwad community.

With modernization and availability of less expensive printed textiles in the market, the Bhadwads slowly stopped wearing tangaliya. The Dangasia weavers started losing their only clientele. Seeing this, many organizations like SAATH and design colleges like NIFT collaborated and conducted design workshops for weavers.

The outcome was a product range in cotton, silk and acrylic which was suitable for the contemporary market. The main challenge in coming up with new products is value addition. The product should complement the composition of dots, bring out the texture of the plain weaved fabric and raised dots and avail the design on both sides of the fabric.

Only if a product evinces these three qualities of the Daana weave, will it be a successful product.

Social Importance

Earlier tangaliya was known only by two communities the Dangasias and the Bhadwads. It was a part of their lives. No special occasion was complete without wearing or gifting a 17tangaliyawovenproduct. With time it has started losing its importance among the traditional wearers.

This craft was unknown to the world until 2007-2008, when it received the GI (Geographical Indication) certification, during the design intervention project by NIFT. After this, there was a complete change in the structure of the craft. The social relevance changed from traditional to contemporary market.

The Dangasia community became well known for their tangaliya weaving. When the project ended the system started to lose its dynamics. Organizations, which were extremely active during those years, slowed things down. Irrespective of this, the craft has attained a certain position in the market and on further encouragement it can prosper even more.