Aranmula Kannadi Mirror

Aranmula Kannadi Mirror comes from Aranmula, a village in the district of Pathanamthitta is well known for its ancient temple dedicated to Lord Krishna and it is also famous for its fine metallurgical art of making metal mirrors which are also known as the Aranmula Kannadi.

WHAT IS THE SPECIALITY OF ARANMULI KANNADI AND HOW IS IT MADE?

Aranmula Kannadi is a handmade metal-alloy mirror. A special alloy is used to manufacture the Aranmula Kannadi. The metal mirror manufactured in Aranmula is a front surface reflection mirror, which eliminates secondary reflections.

The exact metals that form the alloy are said to be a combination of copper and tin. Besides making the right combination of the alloy, the craftsmen get involved in intensive polishing sessions, which would go on for several days to obtain the desired reflective surface.

Even today, craftsmen use traditional, indigenous methods and materials to produce the reflecting wonder called Aranmula Kannadi. It takes great practice and a tremendous amount of focus and patience to produce a perfect mirror piece.

How the secret metal combination found?

A few centuries back the high priest of Aranmula Parthasaradhy temple found that the crown made for the deity was cracked. The local king then summoned the head of the bronzesmith clan and ordered him to make a new crown within three days.

The crown made out of the compilation of copper and tin turned out to be a marvel of art and craft. It was silver in color, brittle like glass, shone with rare brilliance, and when cleaned acquired the quality of reflection.

The makudam or crown as kannadi bhimbom(mirror image) was preserved in the Aranmula temple till 1946. The casters soon worked out the ratios different metals used.

The chieftain of aranmula liberally patronized that craft person and even laid down an order that the mirror should form one of the eight auspicious articles used in all Hindu religion rites including marriages.

They then made a small KUMKUMA CHEPPU or vermilion container, in bronze and fitted it with a small bronze and fitted it with a small bronze mirror on the cover, this becomes very popular among the elite of Malayali society. Under the patronage of a few aristocratic ladies, the vaalkannadi (Handheld mirror) flourished.

There has been the mentioning of the metal mirror in many Puranas including Rig-Veda. Even in the carvings of Khajuraho, there has been a depiction of hand-held mirrors.

The mirror is an oval shape or as per the ancient, it is shaped as the ‘YONNI MUKH’ or Vaginal face. It depicts femininity, just as Shiva Linga depicts masculinity.

There are many temples in which the vaalkannadi is used to symbolize Goddess, i.e. Goddess without form it is a temple dedicated to Goddess Saraswathi, Veena is placed next to the mirror. The mirror has a lot of ritualistic importance.

The Vaalkannadi has been used by the ladies of wealthy families for makeup and also to admire themselves. It has also been an item of a social symbol.

THE EXACT METHODS AND PROCESS OF MAKING THE ARANMULA KANNADI:

A Kowa or crucible made of wrought iron having an approximate capacity of holding 9 Kg of molten metal is cleaned. The pieces of pure chembu (copper), eeyam (tin) and nagam (zinc) are added in proportion.

The mouth of the kowa is sealed with clay. An opening lid made of clay is also provided. Two vertically opposite holes are provided to pour out the molten metal. One of these holes acts as an air vent.

The Kowa is then placed in an open pit furnace charged with burning charcoal. It is then covered with pieces of thondu, as thondu retains the heat. It is heated to about 400 degree Celsius (approximate melting point of brass).

The molten metal is poured onto a flat surface (usually the ground itself). Once cooled, the alloy is then broken into pieces using a chuttika(hammer). The broken pieces are then inspected for the quality of the alloy. If found satisfactory, then it is remelted.

Else more amount of the alloying elements are added. The molten metal is then poured into the preheated mound. It is then left for cooling. Once cooled, the clay mould is broken and the casting is removed.

The casting is checked for any deformities. Usually, the master craftsman prepares four to five mirrors and polishes them at a stretch. When one gets heated he does the polishing for the next one while the other cools.

To achieve high-quality reflective surface the polishing can go on from one to two days. Once the required polished surface is achieved it is then further polished using a piece of cotton cloth.

Then final polishing is done using a velvet cloth. The velvet tends to absorb the oil that was applied earlier on to the mirror. Hence, further polishing is continued on another dry piece of velvet.

The velvet cloth is placed on the ground and the mirror along with wooden blank is moved in the desired direction. Once the satisfactory finish is achieved the disk is just heated to separate it from the wooden blank and the mirror is mounted on a brass fame.

The finished mirror would be brighter and beautiful. The making process of aranmula kannadi contains a lot of efforts, expertise, and patience.

CAN ARANMULI MIRROR BE A REPLACEMENT FOR YOUR DRESSING TABLE MIRROR?

NO. For those of you, who are yet to get it clear – aranmula mirror / aranmula kannadi is not a replacement for your dressing table mirror, or it can’t be made in such a huge size. Instead, this is a mirror with a lot of specialties and it is used as a precious collectible.

Yet, you can use it to view your face/image – but the biggest aranmula kannadi that was made was around 12 inches in diameter, that itself would be at least 10 kilograms in weight with a huge frame size and can be very expensive.

Normally the aranmula kanandi comes in a size range of 2 inches to 6 inches – those are the most popular models, where people buy, gift or keep in their homes/business organizations.

HOW DO I BUY ARANMUALA KANNADI?

Ordering Aranmula Kannadi is now easy, either you can place an order online via an e-commerce website, you can also make a call or e-mail in order to book your kannadi. If you happen to live near the handicraft shop, you can visit and buy the aranmula kannadi.

Most of the customers prefer it to buy online, and by doing so, you have to make sure that the particular model which you are ordering is readily available in stock. A better way is to send an e-mail or call and confirm the availability.

The normal procedure is, when a customer orders a mirror, that is when the artisans will start the process of making a mirror for them. This tells us that each and every mirror is custom made. The manufacturing of the mirror starts after the customer makes a demand for it. It should be noted that it is a time-consuming process.

Also, time to deliver the mirror is very important. Any kind of fastest courier may take at least 2 to 3 business days to deliver the mirror.

Therefore if any of you have a thought in your mind to have the Aranmuli mirror in your house in a few weeks, you’ll have to know that these mirrors are handmade and they take months to come out ready. They cannot be purchased overnight.

HOW TO MAKE SURE THAT THE ARANMULA MIRROR YOU BUY IS NOT FAKE?

Many people are buying aranmula kannadi from various places, which might be selling fake mirrors to them. So how do you verify if the mirror is the original piece?

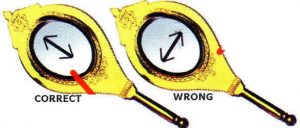

There are many ways to verify it, and the simplest among them is – you should keep your fingertip on the surface of the metal mirror, if you don’t see a gap between your fingertip and the reflective image, that means you have an original in hand. In a regular mirror used all around us, the gap is quite evident.

It is much better and safer to not buy aranmula kannadi from unconfirmed dealers or places.

Since the year 2016, every aranmula kannadi comes with a hologram sticker of the Vishwakarma Nirmaan society to confirm its authenticity. But it is to be noted that you can’t see the hologram in the older mirrors you bought before 2016.

HOW TO MAINTAIN AN ARANMULA KANNADI:

The proper maintenance of the metal mirror requires the mirror to be kept at room temperature and also away from heat and dust.

There is a prescribed method to wipe the mirror to remove finger stains and other marks on it. The wiping movement is restricted to a particular direction and not in all. Therefore it is better asked to take a look at the videos or the guide to know how to maintain the mirror.

This concludes that this mirror is marvelous indeed, Noted for outstanding beauty and shrouded in secrecy, the Aranmula Kannadi is considered a medieval marvel in the annals of metallurgy.

It was in use much before the appearance of modern-day glass mirrors. The technical know-how behind the making of this unique metal mirror is confined to only some households of master craftsmen in Aranmula.

This piece of mirror is a marvelous object to be bought. It is very sure that it would definitely make any place it is kept in, more beautiful and perfect.

The art of making metal mirrors by casting & polished copper-tin bronze was well understood in India & these mirrors were very popular for their clarity, Indeed, the ancient art of making metal mirrors is still practiced without modification, by a few family-based artisans in Aranmula, a small village in southern India.

As traditional as the mirror making technology is the artisan’s belief that the composition of the metal-mirror is divine & that some undisclosed metal alloy with the copper & tin is responsible for the distortion-free images.

THE MAIN FIGURES BEHIND THE ARANMULA KANNADI:

*Shelvaraj A.K (President of the aranmula mirror society)

During an interview, Mr. Shelvaraj said “The imitators are using the combination of tin and copper, but they don’t know the accurate combination of the alloy.

They polish the mirror with grinding and buffering machines. After one or two years of use, the surface of the mirror becomes black and it will fade. The spurious ones are destroying the brand value of the mirror.”

*Aravindakshan N.D ( store manager at Kairali handicraft emporium, a government initiative in Kerala)

During another one of his interviews, Mr. Aravindakshan says “Only a few artisans remain who know the art of making the mirrors and it is important to preserve the tradition, It is a pity that even in Kerala not many people know about the specialty of the mirror.”

*Acharies

At present, only 19 registered craftsmen called “acharis” have the legal right to make the mirror. Why? Because of the number of fake ones floating around in the market.

The craft has been taught to 19 artists who have started their own mirror making units across the state.

Is the government supporting this particular organization?

Yes, certainly. In fact, the government uses aranmula kannadi as an honorable award to award the great figures of India.

And also there are several initiatives from government and private sources to protect and promote the authentic craft. However, the dwindling number of artisans capable of making the perfect alloy and polishing it is creating another problem but however, the government is trying it’s best.