The craft of leather embossing with hand painting was introduced in West Bengal in the 1940s. It was first introduced in Shantiniketan, ‘Abode of Peace’, synonymous with Shri Rabindra Nath Tagore.

A number of crafts were revived in Shantiniketan as creative and practical learning processes were given great priority in this institution. It pioneered the craft of making unique leather items popularly known as Shantiniketan leather.

Embossed patterns and batik work on leather as practiced here are distinctively different from the usual leather crafts. Rabindra Nath Tagore, his wife Protima Devi, stalwarts like Nandlal Bose, and various local craftsmen came together to inspire the youth with innovative designs, materials and techniques in craft forms.

For the first time in the history of Indian crafts, caste barriers were removed in practicing crafts as training and practice were based on an institutional framework. Both men and women are involved in the craft today.

Step by Step making of Leather Embossing

Region of Production

The craft of hand painted embossed leather is practiced only in West Bengal. Birbhum and 24 Parganas are important regions of production.

Producer Communities

There is no specific caste or religious community that practices this craft. Since it emerged in the context of an institution focused on creativity and practical learning, there were no caste barriers to practicing the craft. Training is provided by production units to students interested in learning the craft.

Raw Materials

Leather (coarse and finished), pigment colors (vegetable and imported), PCP chemical, spirit, lacquer, thinner, zipper, thread, adhesive, lining cloth, cotton rope.

Tools

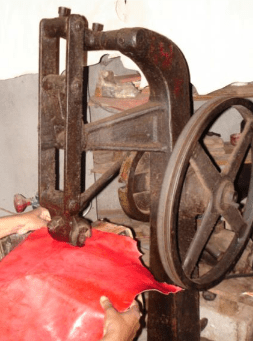

Tuli (brush); thukni (hammer);glass paper weight/glazing machine; scissors; mouth spray; dies; ball press machine.

Process

Leather procured from the wholesale market is immersed in water for about 2 days. It is washed thoroughly and stretched out on the floor to avoid wrinkles. It is then sent to the tannery for coloring. The next stage is to cut it with scissors into desired shapes using cardboard templates. The pieces are polished/ burnished to smoothen the surface and give a luster.

For embossing, the piece of leather is moistened with a sponge. A block is made of the desired design by the acid etching process used in old letter presses. The die is placed in a ball press machine and the leather is sandwiched between the die and a sheet of hard rubber, and strongly compressed. The leather thus takes the imprint of the die.

After drying the embossed leather is ready for color filling or ‘touching’ as it is called locally. Spirit-based dyes are used for the purpose. The embossed areas are dabbed with different colors using a rolled piece of cloth. After drying, the entire surface is colored an even shade using a mouth spray. The embossed leather piece is ready to be stitched into different products after drying. The final stage involves lacquer finish. Here lacquer and thinner are applied (in the ratio of 1:3) to polish the product as well as make it fungus-free.

Product Range

Coin purses, lipstick cases, cosmetic cases, spectacle cases, pen holders, key chains, wallets, bags, purses, piggy banks, cushion covers, moorah (small stool) covers etc.

Changes over the Years

Market

Besides the domestic market, the primary export markets for embossed leather products were Japan and Russia. However, in contemporary times the products are sold in Spain, Italy, Australia and USA as well.

Design

Along with traditional motifs more abstract designs such as geometrics and floral designs have become popular. The products are available in a wide range of colors depending on market requirements.

Technology

Technology up -gradation has been seen in the spray machine that is an alternative to mouth spray. Dies have also been introduced for embossing.