Fond of decorating your house and welcoming guests on festivals or occasions by spreading traditional carpets at your place? Navalgund Durries, are the best thing one can opt for such occasions. Navalgund dhurrie made out of cotton are well known for their excellence in quality of their structure, originality of color and form that makes them unique from another type of floor coverings mats.

Why the name Navalgund?

The name of the town, ‘Navalgund’ means the “hill of peacocks.” This place was famous for our national bird and was later incorporated as a part of the pattern in the jamkhana, which are famous for their colorful designs of peacocks. Jamkhana in local language means floor mats which are widely used as floor coverings for decorations. It is flat, weaved floor coverings made of twisted cotton yarn which are called durrie placed on certain occasions like weddings, personal ceremonies, religious gatherings and other special occasions.

The traditional jamkhanas woven here have types like Pagaddi Atte (Shatranj), Bada phool jamkhana (Geometrical floral motif), Ek mor Jamkhane (1 peacock), Chaar mor jamkhana (4 peacocks), Jainamaz (Muslim praying rug). With the legacy of several generations of manufacturing the Navalgund durries, their specifications and procedure of manufacture are well documented. An alley named Jamkhan galli is named after its famous product, as most of the houses in the area belonged to the traditional weaving families.

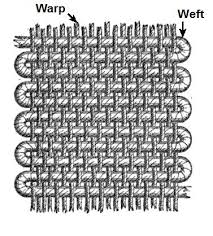

In the process of manufacture, the raw cotton is procured by the weavers from the Karnataka State Handicrafts Development Corporation (KSHDC). Cotton, the unbleached yarn is used for the warp and cotton used for weft. The yarns could also be purchased from the market of Hubli. After procurement of the required material, the pre-weaving process is started. It is a four-stage process.

How are they exactly made?

Following are the steps followed for making these durries:

a). The first step being preparation, which is a set of threads which runs through the length of the durries and is covered by the weft. While warp of the small durries is made in the open yard of the house, in the case of larger size durries of eg 8 × 12 feet size, the warps are made on large grounds.

b). Then a detailed work procedure is followed with sticks to warp the required number of threads.

c). This warp is then shifted to the loom inside the house and weaving is done in a set pattern using warp beams of the looms, sticks and threads.

d). The yarn of the weft is then dyed with dyes of various colours, mixed with water, and the hanks are kept in the dye solution for 20 minutes before removal and drying.

e). The warp is fixed on the loom (that is of vertical design, unlike the horizontal loom used at the ground level at other places in the country) and adequately stretched to obtain the required tension.

f). The weaving is then started by two weavers facing each other. Patterns are introduced in the warp at the appropriate stage of weaving.

g).Vertical and diagonal lines are marked and weaved. The designs are decided by the weavers.

h). Following completion of the weaving process, the durries are removed from the loom, and the over-hanging threads are all trimmed.

i). Tassels, in the form of knots, are made at the end of the warps. The decorative threads of white and other colours are threaded to the edges. A particular feature of these durries is that no two durries are alike in colour and size.

These durries are marketed under two categories as: Jamkhana in sizes of 3 ft × 5 ft, 9 ft × 6 ft and 6 ft x 9 ft; Navalgund-ja-Namaz of 2 ft × 4 ft, which is a prayer mat, exclusively used for offering worship in the mosque or at any other place. Inspection of the durries is carried out by a body of officials from the Development Commissioner (Handicrafts).

It is truly recommendable how talented these artists are! Following a tradition since generations is indeed appreciable. Infact, Jamkhana gali (alley) is where most of these makers live. They have been following the tradition started by their ancestors. Unfortunately, this art of weaving and making such durries is getting extinct due to its expense and less demand.

Hence, few among the community have also stopped weaving these durries and indulged into some other occupation. This business has lost its essence somewhere since people don’t know much about it, which leads to less demand and supply eventually. Hopefully it gains proper attention and helps the world know more about this rare art! Because such kind of ancient tradition truly adds another feather to India’s cap of rich history and diverse culture.